Introduction:

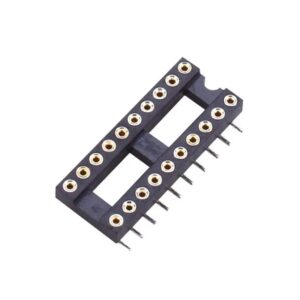

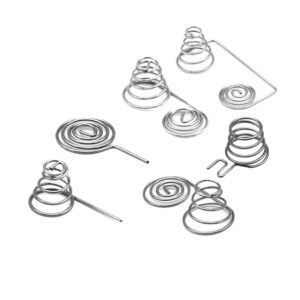

Premium Speed Stamping Components: Brass, Copper, and Stainless Steel Terminal Clamps are expertly crafted from top-tier materials, including brass, copper, and stainless steel SUS304/301, these components offer unmatched performance in a variety of applications. Available in elegant gold, classic silver, sleek black, or custom colors, these clamps undergo meticulous surface treatments like tin plating and nickel plating, ensuring both visual appeal and exceptional corrosion resistance. What sets our components apart is their remarkable tolerance range of 0.02mm-0.1mm, certified through rigorous oxidation tests, including salt spray tests. Meeting and surpassing industry standards, these clamps hold prestigious certifications such as ISO9001, ROHS, and IATF 16949, guaranteeing their quality and reliability. From automotive and medical equipment to household items and furniture manufacturing, these versatile components excel across diverse applications. Experience tailored solutions with our OEM services, allowing you to customize these components according to your specific requirements. To ensure our quality meets your expectations, evaluate our products through complimentary samples. Trust in the superior performance, unmatched precision, and unwavering reliability of our Precision Speed Stamping components to elevate your projects to new heights.

Surface Treatment:

Our Precision Speed Stamping components undergo meticulous surface treatments to ensure superior performance in diverse industrial applications.

-

Tin Plating:

Tin plating involves applying a thin layer of tin, enhancing corrosion resistance and solderability. This treatment results in a smooth and even surface, crucial for electrical applications where precision is paramount.

-

Nickel Plating:

Nickel plating offers unmatched protection against corrosion, wear, and tear. It forms a robust barrier, ensuring the components remain durable and stable under varying conditions. Additionally, nickel-plated surfaces exhibit excellent conductivity, further enhancing their reliability.

-

Silver Plating:

Silver plating enhances electrical conductivity and offers exceptional solderability. Components treated with silver plating boast low contact resistance, making them ideal for applications requiring high electrical performance and reliability.

-

Gold Plating:

Gold plating not only provides outstanding corrosion resistance but also ensures a reliable and low-resistance electrical connection. Widely used in electronics and telecommunications, gold-plated components guarantee consistent, high-quality electrical conductivity, making them indispensable in critical applications.

Specification:

Feature: corrosion resistance

Oxidation test: salt spray test

Certificate: ISO9001, ROHS, IATF 16949

OEM: available

Free samples: available

Sample Time: 7-12 Days

Lead Time: 15-25 Days

Payment Term: T/T, L/C 30% deposits, before the ship to pay the balance end. Freight are quote under your request

Packages Term: plastic bag + Carton + Pallet

Delivery Term: by sea/express

Application: automotive, medical equipment, marine machinery, lighting fixtures, electronics, electrical appliances, household, architectural elements, and furniture manufacturing

Material: brass, copper, carbon steel, phosphor bronze, stainless steel SUS304/301, etc.

Color: gold, silver, black or as per customers’ requirement

Surface treatment: tin plating, nickel plating, silver plating, gold plating, etc.

Tolerance: 0.02mm-0.1mm

These professional surface treatments not only enhance the visual appeal of the components but also guarantee their reliability and functionality. With these treatments, our Precision Speed Stamping components stand as the preferred choice for a wide range of industrial applications, promising unmatched quality and performance.