Description:

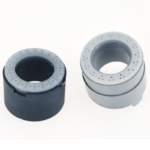

Crafted using advanced overmolding technology, the Plastic Overmolding Shower Nozzle offers durability and customization options for an enhanced shower experience. Designed to optimize water flow and resist wear and tear, this eco-friendly nozzle is easy to install and compatible with various shower systems. With a commitment to quality and safety, it undergoes rigorous testing to ensure reliability, making it a top choice for those seeking innovation and performance in their shower routine.

Key Features of Plastic Overmolding Shower Nozzle:

1.Durable Construction:Utilizes innovative overmolding technology for enhanced durability and long-lasting performance.

2.Customizable Design:Offers personalized design options to tailor appearance and functionality according to user preferences

3.Optimized Water Flow:Precision-engineered to deliver consistent and refreshing water flow while conserving water.

4.Wear and Tear Resistance:Built to withstand daily use, ensuring durability and maintaining quality over time.

5.Easy Installation:User-friendly design facilitates easy installation with minimal effort and time.

6.Eco-Friendly Materials:Crafted from eco-friendly materials to minimize environmental impact without compromising quality.

7.Versatile Compatibility:Compatible with various shower systems, suitable for a wide range of bathroom setups.

8.Safety Assurance:Manufactured to strict quality standards, undergoes rigorous testing to ensure compliance with industry regulations.

Production Process:

- Design and Prototyping: The process begins with creating detailed 3D models using CAD software to define design specifications.

- Tooling and Mold Preparation: Custom molds are created using CNC machines to precisely form the plastic base and overmolding components.

- Injection Molding of Plastic Base: A thermoplastic material is injected into the mold to form the nozzle’s primary structure, ensuring consistent strength and shape.

- Overmolding: A second layer of material, such as TPE or silicone, is injected over the plastic base to provide ergonomic features and enhanced durability.

- Cooling and Solidification: The part is allowed to cool and solidify, ensuring secure bonding of the base and overmolded materials.

- Ejection and Inspection: The nozzle is ejected from the mold and carefully inspected for defects or inconsistencies.

- Post-Processing: Flash removal, polishing, or cleaning may be performed to improve the part’s appearance and functionality.

- Assembly and Packaging: The nozzle is assembled with other components and packaged for shipment, meeting quality standards for durability and performance.