Overview

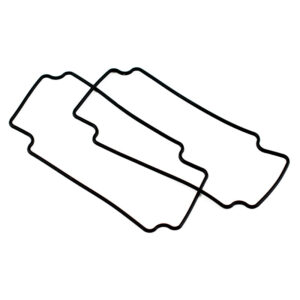

Electrical enclosure gasket is one of the important sealing parts in precision electronics industry.

The design and function of electrical enclosure gaskets can vary depending on the materials, dimensions and factors required for the application, such as dust resistance, water resistance, exposure to water and ice, chemicals, oil and UV light.

The electronic part’s need for general properties such as dust sealing, washdown protection or immersion will also determine the best material for housing gaskets. Housing gaskets and seals are typically constructed of weatherproof and UL 94 rated closed cell foam rubber and silicone foam gasket materials.

Properties of Electrical Enclosure Gasket

- Excellent sealing performance

- Anti-aging, anti-deformation

- Reduce contact and friction between accessories

- High temperature resistance

Production Process of Electrical Enclosure Gasket

Silicone is one of the few low durometer gasket materials that does not contain plasticizers. Among electrical enclosure gaskets, silicone gaskets with a hardness of 10 or 20 are most commonly used.

We provide customized production solutions for customized rubber gasket for electrical enclosures, you can choose gaskets in different colors and sizes. We use compression molding or injection molding to produce silicone gasket parts that meet your requirements. These products are suitable for including precision electronic parts sealing in most industries.