Description:

Silicone O-rings are versatile sealing components used in various industries due to their excellent resistance to extreme temperatures, ozone, and UV exposure. They are primarily manufactured through liquid silicone injection molding or compression molding processes. Liquid silicone injection molding offers high precision and the ability to produce complex shapes consistently, making it ideal for high-volume production. Compression molding is often utilized for larger O-rings or smaller production runs, ensuring strong mechanical properties.Silicone O-rings are renowned for their exceptional durability and sealing performance in demanding environments. These attributes make them indispensable in applications requiring long-term reliability and resistance to extreme conditions.

![]()

Details:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Name | O-Ring |

| Material | Silicone Rubber |

| Application | Industry |

| Color | Customized Color |

| Hardness | 20–90 Shore A |

| MOQ | According To Your Designing |

| OEM | Accepted |

| Sample | Available |

| Size | Custom Size |

| Feature | Heat Resistance |

Benefits of Silicone O-Rings:

– Temperature Resilience: Silicone O-rings excel in both extreme heat and cold environments.

– Resistance to Compression Set: They offer outstanding compression set resistance, ensuring consistent seal performance over time.

– Stability in Ozone and UV Exposure: Highly resistant to damage from ozone and ultraviolet light.

– Oxidation Resistance: Excellent protection against oxidation, contributing to their long-lasting durability.

– Effective Water Sealing: Provides reliable sealing against water intrusion.

– Versatile Softness: Available in softer durometers such as 10, 20, and 30 Shore A, allowing for customized flexibility and application-specific performance.

Silicone O-Rings Manufacturing Process:

- Material Preparation: The silicone rubber is precisely compounded with specific additives to achieve the desired characteristics such as flexibility, hardness, and temperature tolerance.

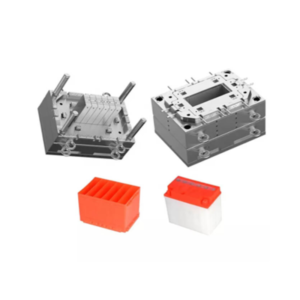

- Molding: The prepared silicone material is shaped into O-rings using either injection molding or compression molding techniques. Liquid silicone injection molding is particularly favored for its accuracy and efficiency in high-volume production, where the silicone is injected into a heated mold to cure and form the O-ring.

- Curing: The molded O-rings undergo a curing process, where they are heated in an oven to induce vulcanization. This step cross-links the silicone polymers, enhancing the O-rings’ mechanical strength, durability, and elasticity.

- Trimming: Post-curing, any excess material or flash is carefully trimmed off to ensure that the O-rings meet precise dimensional requirements and possess a polished, clean finish.

- Inspection: Each O-ring is subjected to a rigorous inspection process to identify any defects, confirm dimensional accuracy, and verify quality standards. This inspection includes testing for hardness, elasticity, and overall appearance.

- Packaging: Once inspected, the O-rings are packaged according to customer requirements. Packaging options vary from bulk to individual packaging, depending on the specific order, and are then prepared for distribution.

![]()

![]()