Description:

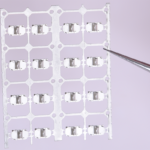

A lead frame is a crucial metal component used to connect semiconductors to larger circuits in devices such as automotive electronics, electrical systems, and printed circuit boards. Its role is vital in ensuring strong semiconductor connections, as even minor defects can cause the entire assembly to fail.

At Thesun Industry, we specialize in manufacturing high-precision, custom lead frames for a wide range of applications, including automotive, electronics, and electrical systems. As a leading provider of stamped metal parts, we deliver personalized solutions that cater to your unique requirements, ensuring your semiconductors perform optimally and reliably. Count on us for top-tier lead frames designed to elevate your product’s efficiency and performance.

Details

- Place of Origin: Xiamen, China

- Brand Name: OEM

- Color: Customized

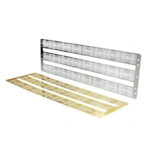

- Material: Copper, Aluminum, Copper Alloys, etc.

- Size: Custom

- MOQ (Minimum Order Quantity): Based on your requirements

- Packing: Customized

- Process Technology: Metal Stamping

- Lead Time: Approximately 30 days

Advantages of Lead Frames:

- Improved Durability for Consistent Performance

- Exceptional Electrical Conductivity for Peak Efficiency

- Economical Mass Production for Cost-Effective Solutions

- Tailored Designs to Address Unique Application Requirements

Production Process:

-

Material Selection and Preparation

Carefully select and prepare materials such as copper, brass, aluminum, or stainless steel, tailored to the specific needs of the application.

-

Tooling and Die Design

Develop precise tooling and die designs based on part specifications to ensure accurate, repeatable production.

-

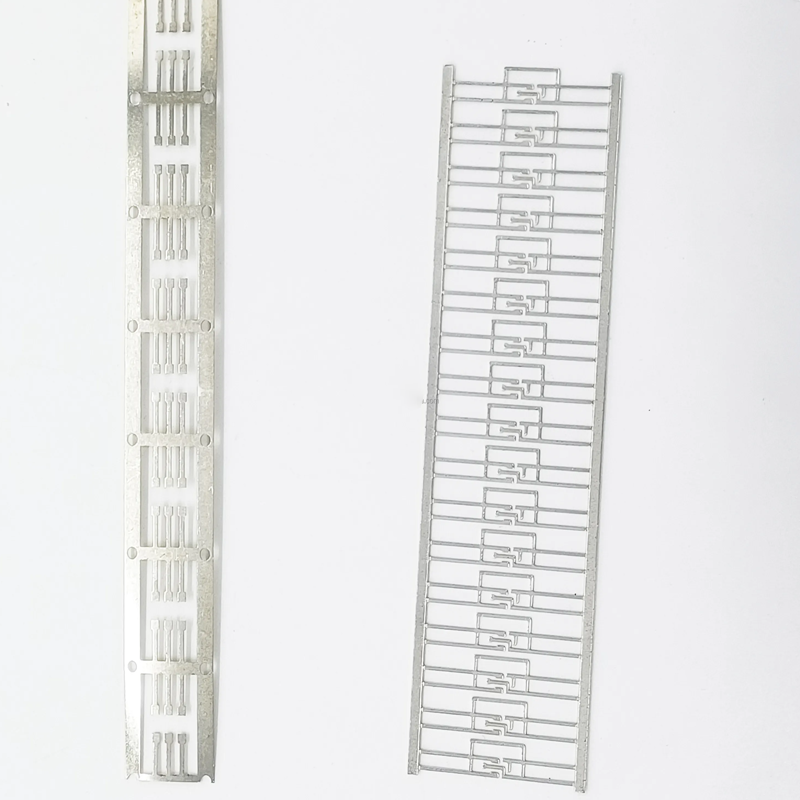

Metal Stamping

Feed the prepared material into a stamping press to cut, shape, and form the lead frames according to the established design.

-

Cleaning and Surface Treatment

Thoroughly clean the stamped lead frames and apply various surface treatments—such as coatings or plating—to enhance durability and functionality.

-

Inspection and Quality Control

Perform stringent inspections and quality control measures to ensure the lead frames meet exact dimensional and performance standards.

-

Final Assembly and Packaging

Complete the assembly of lead frames or package the finished components, ensuring they are protected during transit.

Surface Treatment Options:

-

Passivation

A process to enhance corrosion resistance by creating a protective oxide layer on the metal surface.

-

Gold Plating

A thin gold coating applied for improved conductivity, corrosion resistance, and aesthetic appeal in electronic applications.

-

Silver Plating

A silver coating that enhances conductivity and solderability, commonly used in electronic components.

-

Nickel Plating

A nickel layer to improve hardness, corrosion resistance, and wear resistance, widely used in automotive and industrial applications.

-

Tin Plating

A tin coating that improves corrosion resistance and solderability, frequently used for electronic connectors.

Our Facility:

Our state-of-the-art facility is equipped with advanced machinery to ensure the highest standards of production quality. We operate 25 punch presses ranging from 25 to 300 tons, along with precision wire EDM, grinding, welding, and ultrasonic cleaning systems.

We also offer a variety of metal plating services, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing, all performed in our advanced plating facilities. These processes ensure consistent finishes, superior durability, and excellent corrosion resistance, meeting industry standards.

Certified to ISO 9001 and IATF 16949, our factory integrates automated production lines, cutting-edge equipment, stringent quality control, and premium plating capabilities to deliver top-tier metal stamping products.