Overview

Laser Instrument Engine Panel Keypad Silicone Button is a cutting-edge solution forged from 100% silicone, offering a Shore A hardness range from 30° to 80°. Versatile in design, it comes in classic Black, sophisticated Gray, or can be fully customized to meet specific preferences. Engineered with eco-friendly materials, this keypad is a testament to our commitment to sustainability. Elevate your product identity with logo options like Silk Printing and Laser Etching, combining aesthetics with lasting performance. Built to withstand demanding applications, it finds its niche in Agricultural Ground Laser Instruments and Engine Panels, showcasing its versatility and adaptability. Certified for excellence with ISO9001-2015 and IATF16949, our Laser Instrument Engine Panel Keypad Silicone Button stands as a mark of quality and precision. Meticulously packed in a plastic bag and carton, it arrives ready for seamless integration into your systems.

Specification

Material: 100% Silicone

Hardness: shore A 30°~80°

Color: Black, Gray or Customized

Design: Customerized Designs

Feature: Eco-Friendly

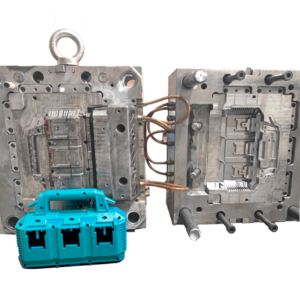

Molded Way: Compression Molded

Surface Protective: PU Coating, Matte Smooth Coating, Epoxy Coating

Logo type: Silk Printing, Laser etching

Usage: Agricultural Ground Laser Instrument, Engine Panel

OEM: Available

Certificate: ISO9001-2015, IATF16949

Packing: Plastic bag & Carton, Customized Packing

Packing: Plastic Bag & Carton

Why Choose Us

- Confidentiality: Your ideas and designs are treated with the utmost confidentiality, ensuring the protection of your intellectual property.

- In-House Compound Formulating: We have a complete in-house facility for custom compound formulating and mixing, allowing us to tailor solutions to your specific needs.

- Expertise in Design and Engineering: Our professional design and mold maker engineering teams provide comprehensive OEM/ODM services.

- Diverse Manufacturing Capabilities: We offer a range of manufacturing techniques, including injection, injection transfer, compression, extrusion, and silicone liquid capabilities.

- Quality Assurance: Rubber compounds undergo rigorous testing before production to guarantee consistent quality.