Overview

Material Selection: Customers can choose from a range of plastic materials, such as polypropylene, polyethylene, or other specialty plastics, based on their specific requirements for durability, resistance to temperature fluctuations, and chemical resistance.

Size and Shape: The battery box can be customized in terms of its dimensions and shape to ensure a perfect fit within the vehicle’s engine compartment. This customization is vital for accommodating different battery sizes and optimizing the use of available space.

Color and Branding: The battery box can be produced in custom colors to match the vehicle’s aesthetics or branding. This allows for a cohesive and branded appearance

Quality Control: The customization process should include strict quality control measures to ensure that the customized battery box meets industry standards and specific customer requirements.

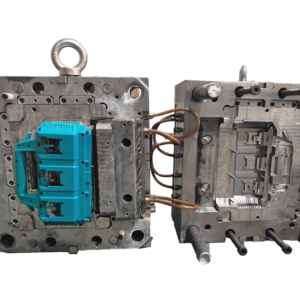

Plastic Injection Molding

The flexible and adaptable nature of injection molded plastic parts and devices make them ideal for the automotive industry. We specialize in the design and manufacturing of injection molded components for:

- Electrical wiring systems

- Interior Class A finish components

- Speakers, audio/visual systems

- Bezels, knobs, mudguards, bumper supports

- Shifter knobs, console lids, electrical covers

- Various vehicle substrates

We provide plastic injection molding services to make parts and components for virtually any automotive application upon request.

Plastic Automotive Parts and Components

From concept to completion, YJC’s experienced team of industrial plastics experts provides comprehensive plastic injection molding and extrusion services encompassing the entire project life cycle including:

• Market and consumer insights

• Ideation and innovation

• Design and engineering assistance

• Custom mold making and tooling

• Rapid prototyping and testing

• Assembly, packaging and delivery