Overview

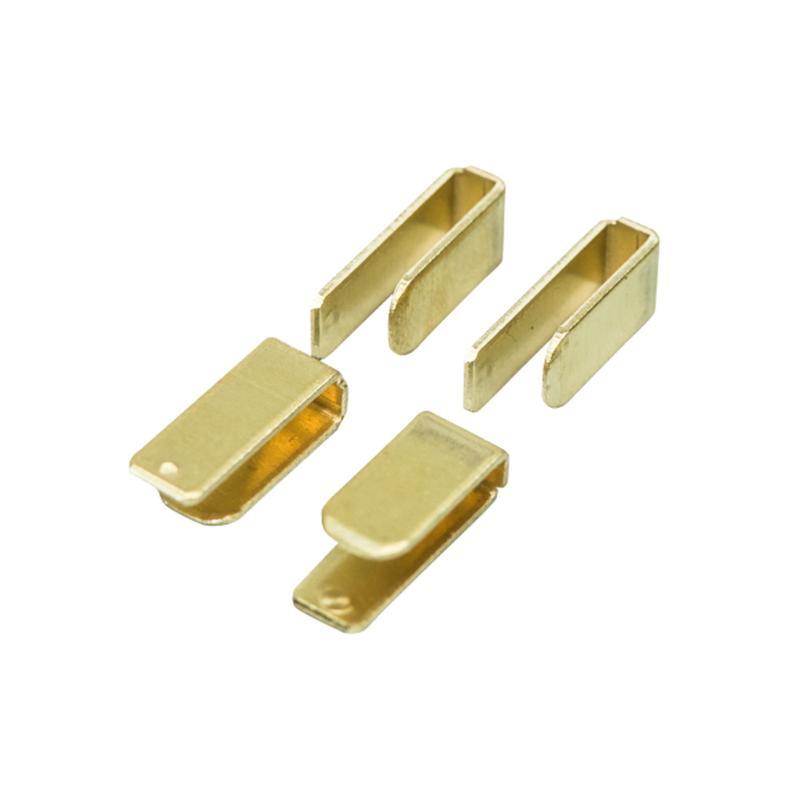

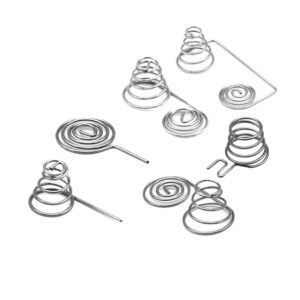

The precisely engineered electrical contact metal components are crafted from high-quality materials such as carbon spring steel, alloy spring steel, stainless spring steel, copper alloy, and nickel alloy. These materials are chosen for their durability and excellent conductivity. Advanced surface treatments, including galvanization, nickel plating, black oxide coating, dacromet finishing, chrome plating, and nylok treatment, are applied to enhance both corrosion resistance and mechanical strength. These customizable metal parts are tailored to specific dimensions based on customer requirements, finding applications in network devices, communication equipment, computers, household appliances, distribution systems, and educational toys.

Specification

Material: carbon spring steel, alloy spring steel, stainless spring steel, copper alloy, nickel alloy

Surface treatment: galvanized, nickel plated, black oxide, dacromet, chrome-plated, nylok, white washing, phosphate, gold plated, anti-corrosion coating, etc

Size: dimensions according to customers’ requirements

Application: network devices, communication equipment, computers, household appliances, distribution systems, and educational toys, among others.

Sample Time: 7-12 days

Lead Time: 15-25 days

Payment Term: T/T, L/C 30% deposits, before the ship to pay the balance end. Freight are quote under your request

Packages Term: carton and pallet

Delivery Term: by sea/express

Common Surface Treatments

- Galvanized: Metal parts are coated with a zinc layer, boosting corrosion resistance and overall durability.

- Nickel Plated: A nickel layer is applied, ensuring excellent corrosion resistance and a polished appearance.

- Black Oxide: Metal parts undergo a chemical reaction forming a black oxide layer, enhancing corrosion resistance and providing a sleek black finish.

- Dacromet: An organic coating is applied, enhancing corrosion resistance and ensuring longevity and reliability.

- Chrome-Plated: A chrome layer is electroplated, offering superior corrosion resistance and an attractive reflective finish.

These surface treatments for our Electrical Contacts High Precision Stamped Metal Parts not only enhance their longevity but also improve their functional and aesthetic qualities, ensuring optimal performance across various applications.