In the world of manufacturing, metal stamping is a crucial process that shapes and forms metal into desired components. Among the various techniques available, hot metal stamping and cold metal stamping stand out as two prominent methods. This blog will delve into the differences between these two processes, highlighting their unique characteristics, advantages, and applications. At Thesun Industry, we pride ourselves on our expertise in both hot and cold metal stamping, ensuring that our clients receive the best solutions tailored to their needs.

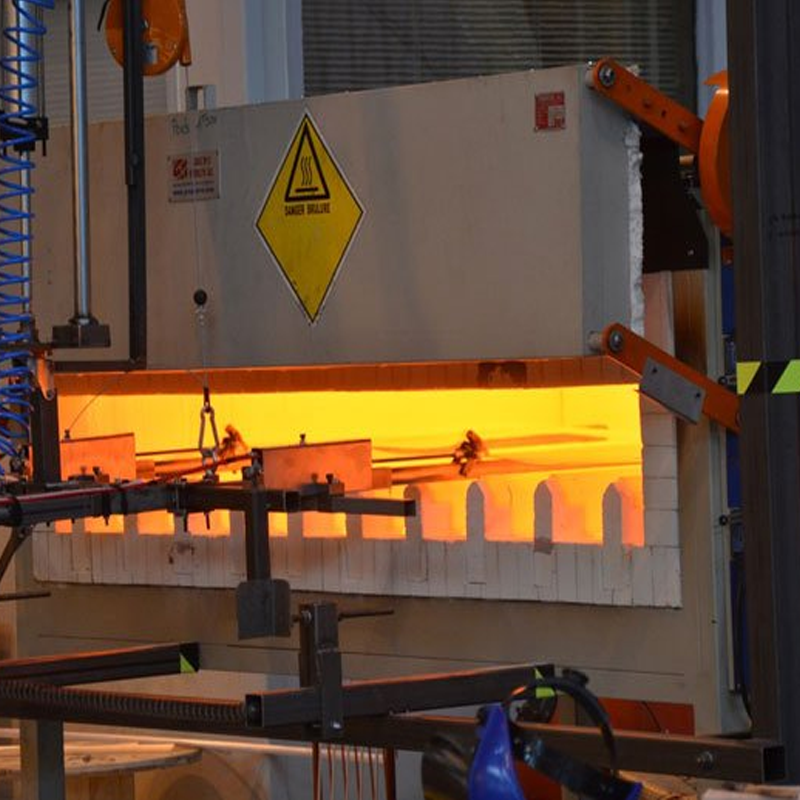

Understanding Hot Metal Stamping

Hot metal stamping involves heating metal sheets to high temperatures before they are shaped into components. This process allows for greater malleability, enabling the metal to be formed into complex shapes without cracking or breaking. The high temperatures used in hot stamping typically range from 900 to 1,200 degrees Fahrenheit, making it ideal for materials like aluminum and high-strength steel.

Advantages of Hot Metal Stamping

One of the primary advantages of hot metal stamping is its ability to produce lightweight yet strong components. The process enhances the material’s ductility, allowing for intricate designs that would be challenging to achieve with cold stamping. Additionally, hot stamping can improve the mechanical properties of the metal, resulting in parts that are not only lighter but also more durable.

| Advantages of Hot Metal Stamping |

| Enhanced ductility |

| Ability to create complex shapes |

| Improved mechanical properties |

| Lightweight components |

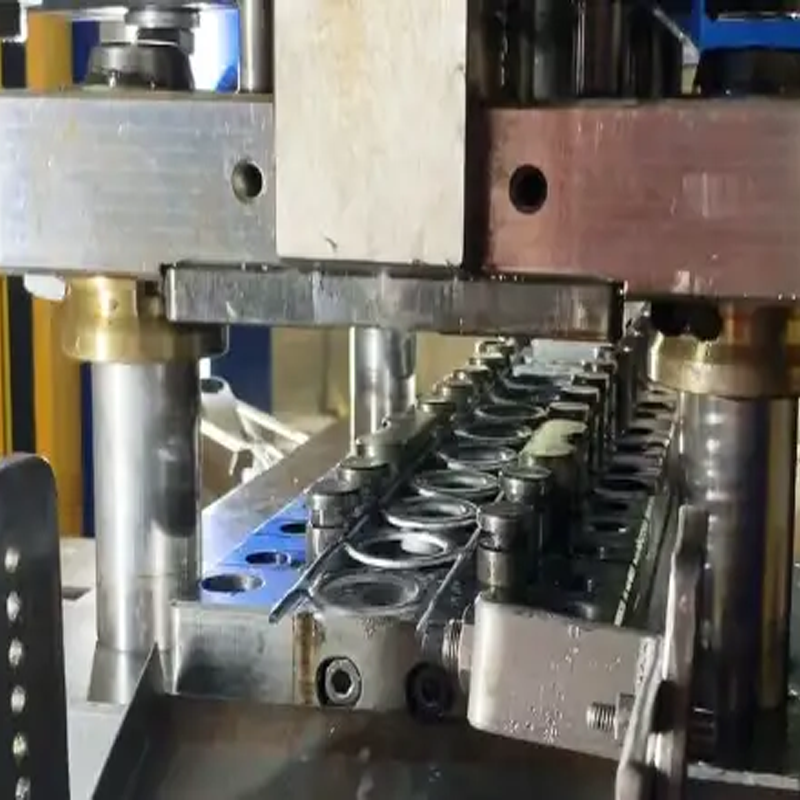

Exploring Cold Metal Stamping

In contrast, cold metal stamping is performed at room temperature, which means the metal is not heated before shaping. This method is often used for materials that do not require the malleability provided by heat. Cold stamping is typically faster and more cost-effective than hot stamping, making it a popular choice for high-volume production runs.

Benefits of Cold Metal Stamping

Cold metal stamping offers several advantages, particularly in terms of precision and surface finish. The process allows for tighter tolerances, resulting in components that fit together seamlessly. Additionally, cold stamping can produce parts with a superior surface finish, reducing the need for additional machining or finishing processes.

| Benefits of Cold Metal Stamping |

| High precision |

| Superior surface finish |

| Cost-effective for high volumes |

| Faster production times |

Key Differences Between Hot and Cold Metal Stamping

While both hot and cold metal stamping serve the same fundamental purpose of shaping metal, the differences in their processes lead to distinct outcomes. The choice between hot and cold stamping often depends on the specific requirements of the project, including material type, desired properties, and production volume.

Material Considerations

Hot metal stamping is typically used for materials that benefit from heat treatment, such as high-strength steel. In contrast, cold stamping is suitable for a wider range of materials, including aluminum, brass, and stainless steel. Understanding the material properties is crucial in determining the appropriate stamping method.

Production Efficiency

Cold metal stamping generally offers higher production efficiency due to its faster cycle times. However, hot stamping can be more efficient for producing complex shapes that would require multiple operations in cold stamping. Evaluating the production requirements is essential for selecting the right method.

Applications of Hot and Cold Metal Stamping

Both hot and cold metal stamping have their unique applications across various industries. Hot stamping is commonly used in the automotive sector for producing lightweight structural components, while cold stamping is prevalent in electronics, appliances, and consumer goods.

Industry-Specific Uses

- Hot Metal Stamping: Automotive parts, aerospace components, and high-strength structural elements.

- Cold Metal Stamping: Electronic housings, brackets, and decorative elements.

Thesun Industry Is Your Partner in Metal Stamping Solutions

At Thesun Industry, we specialize in both hot and cold metal stamping, providing our clients with tailored solutions that meet their specific needs. Our state-of-the-art facilities and experienced team ensure that we deliver high-quality components with precision and efficiency. We understand the importance of choosing the right stamping method, and we are here to guide you through the process.

Why Choose Thesun Industry?

- Expertise: Our team has extensive knowledge and experience in both hot and cold stamping processes.

- Quality Assurance: We adhere to strict quality control measures to ensure that every component meets industry standards.

- Customization: We offer customized solutions to meet the unique requirements of each project.

- Customer Support: Our dedicated customer support team is always available to assist you with any inquiries or concerns.

Conclusion

In conclusion, understanding the differences between hot and cold metal stamping is essential for making informed decisions in the manufacturing process. At Thesun Industry, we are committed to providing our clients with the best metal stamping solutions tailored to their specific needs. Whether you require lightweight components or high-precision parts, we have the expertise and resources to deliver exceptional results.

We invite you to reach out to us with any questions or to discuss your upcoming projects. Our team is eager to assist you in finding the perfect metal stamping solution that aligns with your goals. Let’s work together to bring your ideas to life!