Overview:

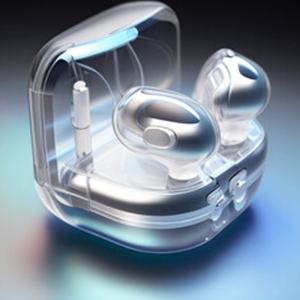

The Customized BPA Free Baby Medicine or Milk Feeder Dispenser with Plastic box is a specialized device designed to facilitate the administration of medicine or milk to infants,which manufactured by injection molding This dispenser is crafted with BPA-free plastic material, ensuring the safety of the baby’s health. Its construction typically involves precise molding techniques to create a user-friendly design that is easy to handle and clean. The dispenser is equipped with measurements for accurate dosage delivery, and its sealed plastic box provides convenient storage and portability. Its advantage lies in its practicality and reliability, offering parents a hassle-free solution for feeding their babies medication or milk with precision and ease.

Details:

| Material: | Silicon,rubber,plastic | Pattern Type: | Cartoon |

| Material Feature: | BPA Free | Flow Velocity: | Medium Flow |

| Age Range: | 0-12 Month, 2-4 Years, >4 years old | Handle: | Yes |

| Product name: | Baby Feeder | Size: | Custom |

| Weight: | 36.8g | Feature: | Funny Toys/Safe/Soft |

| Color: | Customized Color | Service: | OEM |

| MOQ: | 100pcs | Port: | Xiamen |

The production process of Baby Dispenser:

-

Design and Engineering:

Initial stage involves conceptualizing and designing the baby dispenser. Engineers create detailed blueprints considering functionality, safety, and ergonomics.

-

Material Selection:

Careful selection of materials follows, focusing on safety and durability. BPA-free plastics are commonly chosen for their non-toxic properties.

-

Mold Design and Fabrication:

Once materials are chosen, molds are designed based on product specifications. Precision molds are fabricated to exacting standards to ensure consistent quality.

-

Injection Molding:

The chosen plastic material is melted and injected into the molds under high pressure. This process forms the desired shape of the baby dispenser components.

-

Cooling and Solidification:

After injection, the molds are cooled to allow the plastic to solidify and take shape. Controlled cooling ensures proper formation and prevents defects.

-

Assembly:

Different components of the baby dispenser are assembled, including measuring chambers, lids, and dispensing mechanisms. Each part is meticulously fitted together.

-

Quality Control Testing:

Rigorous testing is conducted to ensure the functionality, safety, and durability of the baby dispenser. This includes checks for leak resistance, accurate dosing, and material integrity.

-

Packaging and Distribution:

Finally, the assembled baby dispensers are packaged securely and prepared for distribution to retailers or direct to consumers. Packaging is designed to protect the product during transit and attract consumers on shelves.

-

Post-production Support:

Ongoing customer support and feedback mechanisms are established to address any issues and continuously improve the product based on user experience.

The Advantages of Baby Dispenser:

Precision Dosage Delivery:

- Ensure accurate measurement of medicine or milk for precise dosage delivery to infants.

Convenient Storage:

- Equipped with a plastic box for secure and hygienic storage of the dispenser, making it portable and easy to carry.

BPA-Free Material:

- Crafted from BPA-free plastic, ensuring the safety and health of babies during feeding.

Easy-to-Clean Design:

- Designed with user-friendly features for effortless cleaning, maintaining hygiene for baby’s health.

Ergonomic Handling:

- Ergonomically designed for comfortable handling, facilitating easy and stress-free feeding experiences for parents and caregivers.