Overview:

Silicone keyboard molds are precision-engineered tools used to manufacture silicone keyboard covers, ensuring perfect fit and optimal functionality. We offer comprehensive customization services, including sample-based customization to replicate and enhance existing designs, and full customization to tailor every aspect of the mold to your specific needs. Our OEM services allow us to create entirely new designs based on your concepts, managing everything from initial design to final production. Additionally, we provide various surface texture treatments such as polishing, matte, VDI, and SPI to enhance the final product’s appearance and functionality. Our expertise ensures high-quality, innovative solutions that meet your exact requirements and stand out in the market.

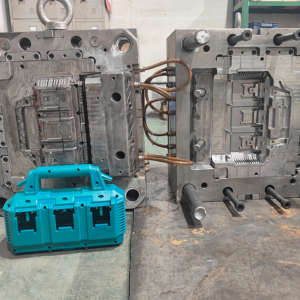

![]()

Features:

| Attribute | Details |

| Shape | Customized shape |

| Minimum Order | Small orders accepted |

| Lead Time | 3-6 weeks after mold design confirmation |

| Drawing Format | .stp, .step, .igs, .stl, .dwg, .pdf |

| Surface Treatment | Matte, common polishing, mirror polishing, texture, laser engraving, powder coating (painting), printing, segmented colors, mixed colors, etc. |

| Application | Automotive, machinery, bathroom facilities, medical, household electrical appliances, etc. |

| Performance | High/low temperature-resistant, wear-resistant, high tensile strength, all available |

| Mold Material | No. 50 steel, No. 45 steel, P20, 8407, H13, 718H, etc. |

| Mold Life | 100-500K shots |

| Mold Testing | All molds are thoroughly tested before shipment. Videos of mold trial runs are available. |

| Inspection | 100% inspection by QC and QA before shipping |

Customization Service for Silicone Keyboard Molds:

– Design Consultation:

Collaborate with clients to understand specific design requirements and preferences.

– Technical Drawings:

Create detailed technical drawings and specifications based on client input.

– Material Selection:

Assist in choosing appropriate materials for both the mold and the final product to ensure optimal performance.

– Tooling Development:

Develop custom tooling and molds tailored to meet precise specifications and production needs.

– Prototype Production:

Produce prototypes to validate design, functionality, and material choices before full-scale production.

– Mold Fabrication:

Utilize advanced manufacturing techniques to create high-quality, durable molds.

– Surface Finishing:

Apply various surface treatments, including polishing, coating, and texturing, to meet aesthetic and functional requirements.

– Testing and Validation:

Conduct rigorous testing of molds to ensure they meet quality standards and performance expectations.

– Adjustments and Iterations:

Make necessary adjustments and refinements based on prototype testing and client feedback.

– Production Support:

Provide ongoing support throughout the production process, including troubleshooting and maintenance.

– Quality Assurance:

Implement stringent quality control measures to ensure the molds meet industry standards and client specifications.

– Delivery and Installation:

Manage logistics for timely delivery and offer installation support to ensure seamless integration into the production line.

The Advantages of Silicone Keyboard Molds:

1.High Dimensional Accuracy

Our molds are designed and manufactured with precise engineering to ensure exact replication of product specifications, reducing the risk of defects and minimizing the need for post-production adjustments.

2. Enhanced Durability

Constructed from high-quality steel and treated with advanced surface finishes, our molds are engineered to withstand high-pressure conditions and extensive use, extending their service life and reliability.

3. Superior Surface Quality

We offer a range of surface treatments, including polishing and texturing, to achieve optimal finish and functionality. This ensures that the final products exhibit excellent surface quality and consistency.

Factory Show:

We utilize 3D projectors, sealing testers, elasticity measurement tools, durometers, and a qualified QC team.Furthermore, our mechanical equipment includes an AutoDryer Line, automatic screen printing machines, 3D measuring instruments, automatic high-speed doming machines,die-cutting machines, automatic die-cutting machines, CNC machines, and more.