Basic Information:

| Attribute | Details |

| Trade Term | FOB,CIF,EXW |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Suitable Material | ABS |

| Transport Package | custom |

| Origin | Xiamen,China |

The Introduction of Injection Molding:

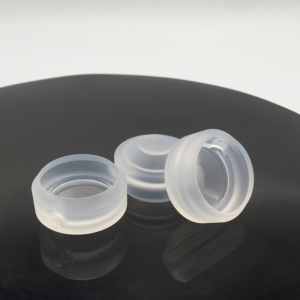

Injection molding machines, alternatively referred to as injection molders or molding machines, are pivotal apparatuses for fabricating plastic articles of diverse configurations from thermoplastic or thermosetting polymers. Categorized into vertical, horizontal, and all-electric variants, these machines heat plastic to molten state and exert significant pressure to inject it into the mold cavity, ensuring complete filling.

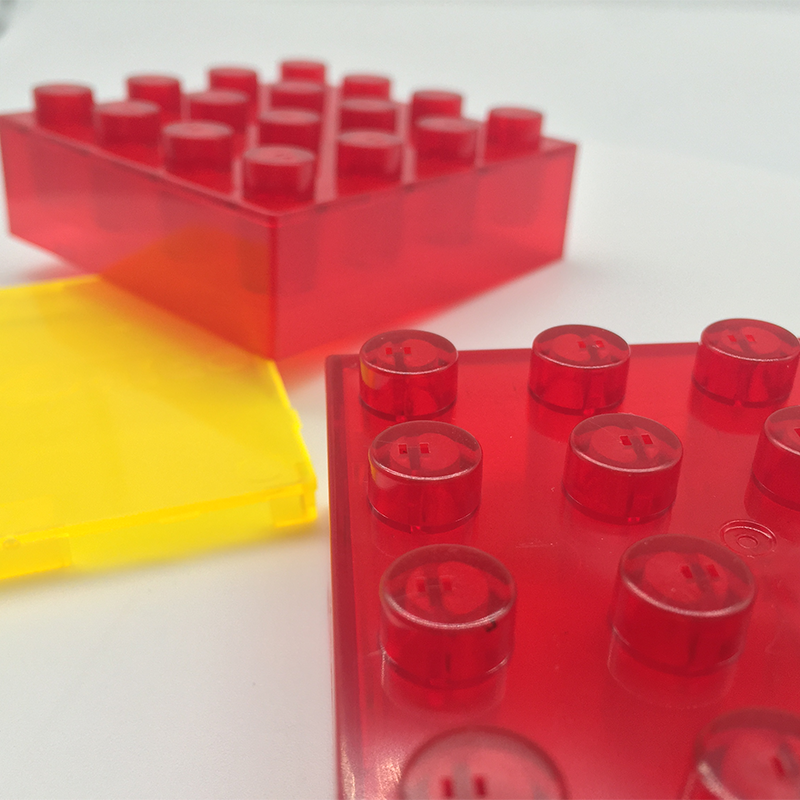

Production Process of ABS Plastic Injection Molding Toy Bricks

- Material Preparation: ABS plastic pellets are sourced and prepared for injection molding.

- Mold Preparation:Molds for toy bricks are designed and fabricated to exact specifications.

- Injection Molding:The ABS plastic pellets are melted and injected into the mold cavities.

- Cooling: The molten plastic solidifies in the mold under controlled temperature and pressure.

- Ejection: Once cooled, the toy bricks are ejected from the mold.

- Quality Control:Toy bricks undergo inspection for defects and dimensional accuracy.

- Finishing Touches: Any excess material is trimmed, and the bricks are ready for packaging.

Request for Quick Quotation:

- Provide Project Details:Please specify the quantity, size, and design requirements for the toy bricks.

- Material Preference:Indicate any specific preferences for ABS plastic material.

- Customization Options:Detail any desired customization such as color, texture, or additional features.

- Deadline:Please provide the desired delivery timeline for the toy bricks.

- Contact Information:Include your contact details for prompt communication and quotation submission.