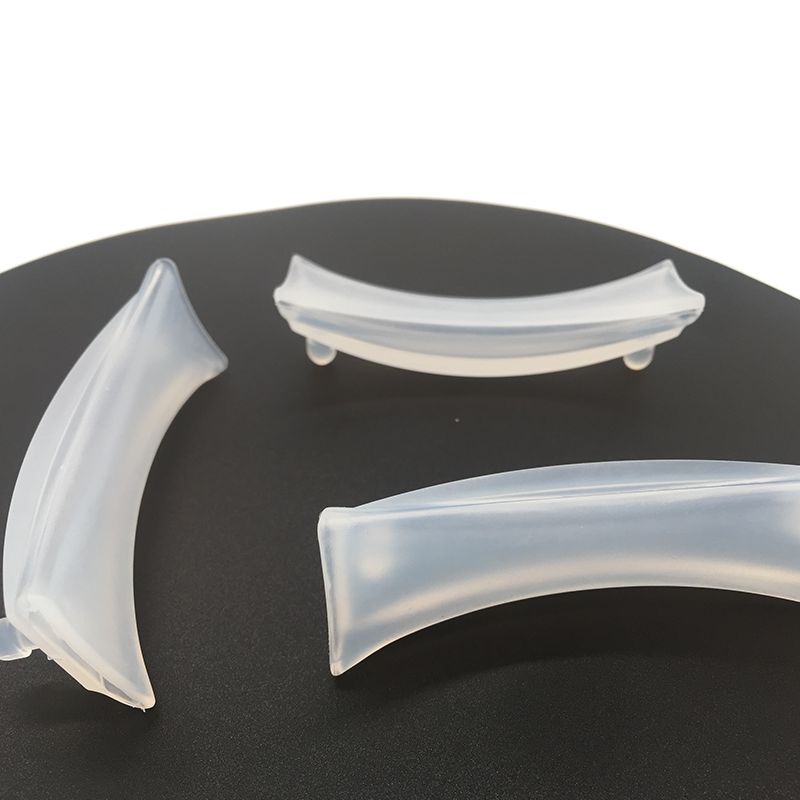

Overview:

Medical Silicone valve seal, also known as silicone diaphragm valves, diaphragm seals, or seals, separate fluids or gases with minimal movement or pressure differential. They are commonly used in medical devices such as valves, pumps, ventilators, and resuscitators. Dynamic diaphragms, on the other hand, transmit force or pressure while maintaining a seal between stationary and moving parts. These diaphragms can be used in fuel and liquid metering and gas control systems for residential and industrial heating. They can be manufactured by compression molding or liquid injection molding (LIM) from liquid silicone rubber (LSR), which is preferred by the medical industry for its inertness, biocompatibility, implantability, and resistance to various sterilization processes.

Advantages of Our Silicone Membrane/Valve/Seal/Gasket/Diaphragm:

- Superior Sealing Performance:Our products offer exceptional sealing, effectively blocking liquids while allowing the passage of gases. With precise molding techniques, we ensure a smooth seal without burrs or flash.

- FDA Grade Material:Crafted from FDA-approved silicone, our membranes and seals are non-toxic, tasteless, and environmentally safe, making them suitable for medical applications.

- Premium Silicone Material:Utilizing 100% silicone material, our products boast excellent resistance to high and low temperatures, weather conditions, ozone exposure, aging, and electrical properties.

Our Benefits:

- Advanced Mold-Making Expertise (Established in 1998)

- Competitive Pricing: Direct Manufacturer Sourcing

- Expert Design Team: Comprehensive Support in Technology, Production, Design, and Artwork

- Rigorous Production and Testing: Adherence to ISO9001 Standards

- State-of-the-Art Facilities: Comprehensive Production Plant, Equipment, and Environment