Description:

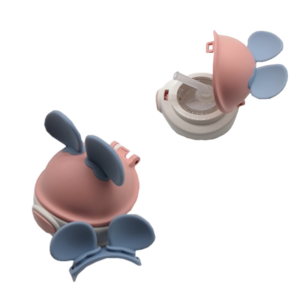

A silicone showerhead is a shower accessory that comes in a variety of shapes including round, square and single nozzle designs. It has multiple uses and goes by various names such as silicone replacement nozzle, rain shower head and bathroom faucet washer. The soft silicone nozzles are less likely to clog and require minimal maintenance other than routine cleaning to remove limescale buildup. Made of food-grade silicone, these showerheads can withstand temperatures from 0 to 90 degrees Fahrenheit without deforming and are compatible with water pH levels from 5 to 9.

Details:

| Service | OEM |

| Part Material | Silicone or rubber (NR,NBR,SBR,BR,IR,CR,EPDM,IIR,(FKM),SIR,PU,ACM,CO,etc) |

| Material Hardness | Silicone about 20~90 Shore A; rubber about 20~90 Shore A |

| Color | Customized according to Pantone colors |

| Appearance | as customer’s requirement |

| Drawings | 2D OR 3D acceptable |

| Temperature Resistance | 0~90degree centigrade |

| Tolerance | 0.05mm |

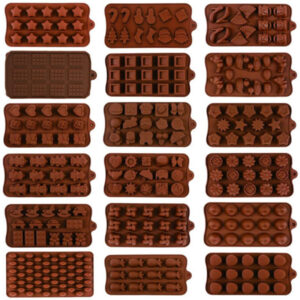

| Technology | Hot pressing molding or injection Molding |

| Quality control | internal QC control |

| Food grade material | FDA or LFGB |

| MOQ: | Amount: More than 500/pcs each part(depends on specific part) |

| Package | Normally PE bag+carton or customized as customer’s request |

| Trade Term | Ex-works; FOB Xiamen; CIF |

| Payment Term | Sample mold: 100% prepaid, MP Mould: 50% deposit by T/T in advance, balance 50% paid after samples approval |

| Goods: 50% deposit, 50% before shipment | |

| T/T, L/C, Western Union, PAYPAL | |

| Lead time | 5~10 days for the first article,10~25 days for MP parts (depends on part structure ) |

| Specification | Confirm to ISO-9001 and ROHS Directive Compliant Green Products |

Our advantages:

Our advantages:

- Competitive Pricing:Benefit from direct sourcing.

- Experienced Team: Skilled R&D engineers, workers, and QC personnel ensure top-quality products.

- Efficient Molding:Short turnaround for mold tooling with in-house facilities.

- Dust-Free Environment:Manufacturing in a clean silicone rubber plant.

- Eco-Friendly Materials: Certified by ROHS, SGS, ISO FDA, and LFGB for environmental safety.