Welcome to Thesun Industry, where we reveal the latest trends and innovations in electronic components. Today we are pleased to introduce you to the fascinating world of silicone switch backlight design. Yes, you heard that right—we’re digging into the details of how to shine a light on those trusty silicone switches we often take for granted. So, buckle up and get ready to embark on an inspiring journey with us!

Now, let’s get down to business. Backlighting design for silicone switches is an important aspect of product development in various industries including consumer electronics, automotive and industrial applications.Silicone switches, often referred to as LED-illuminated rubber switches, exhibit light transmission when powered on, hence the name “backlit silicone switches.” The light transmission effects vary depending on the device requirements. So, how do you design the perfect LED-illuminated switches for your device?

Key Elements of Backlit Silicone Switches

The illumination in silicone switches is achieved through LEDs. This can be done by laser etching icons, symbols, or graphics onto the surface, integrating light pipes into the silicone rubber, or making the entire switch button transparent or semi-transparent. Each method caters to different design needs and enhances the visual appeal and functionality of the switches.

The integration of backlighting not only enhances the aesthetics of the switches, but also improves their functionality and usability in low-light conditions.In this comprehensive guide, we’ll explore the key considerations, design principles, and best practices for implementing backlighting in silicone switches.

First, it’s important to understand the underlying technology behind silicone switch backlighting. LED (Light Emitting Diode) technology has revolutionized the way switches are illuminated, providing energy-efficient, long-lasting and versatile lighting solutions. For silicone switches, the use of LEDs allows for uniform illumination, precise control of light intensity, and customization of colors to meet specific design requirements. Additionally, advances in LED technology have led to the development of ultra-thin and flexible light sources, making them ideal for integration with silicone switches.

When designing the backlighting of silicone switches, it is important to consider the overall user experience. The placement and distribution of light sources should be carefully planned to ensure that the lighting is evenly distributed over the switch surface. This not only enhances visual appeal, but also facilitates easy identification and operation of the switch, especially in dimly lit environments. In addition, the choice of backlight color can play an important role in enhancing the user interface, providing visual cues for different functions, or indicating switch status.

In addition to aesthetics, the functionality of the backlight design cannot be ignored. The backlight should complement the tactile feedback and actuation of the silicone switch, ensuring user interaction is seamless and intuitive. In addition, the durability and reliability of the backlight system are critical, especially in applications where switches are subjected to harsh environmental conditions. Therefore, choosing high-quality materials and sturdy construction for your backlight assembly is critical to ensuring long-term performance and longevity.

As we delve deeper into the world of backlight design for silicone switches, it is important to address the technical considerations that impact backlight implementation. Electrical characteristics, thermal management, and compatibility with switch components must be carefully evaluated to ensure seamless integration and optimal performance. In addition, the design should consider power efficiency and thermal dissipation to prevent overheating and maximize the life of the backlight system.

When designing backlit silicone switches, several methods can be employed to achieve illumination, each with its own advantages and considerations. The primary techniques include laser etching, adding light pipes, and using semi-transparent silicone buttons. Here’s a detailed look at the differences and benefits of each approach:

Semi-Transparent Silicone Buttons

Semi-transparent silicone buttons allow light to diffuse through the material, creating an ambient lighting effect. However, this method can result in light loss or optical dispersion, as the light spreads in all directions. While this can create a pleasant atmospheric glow, it may reduce the intensity of the illumination on specific icons or symbols.

Pros:

– Creates a soft, ambient lighting effect.

– Enhances the overall aesthetic of the device with a uniform glow.

Cons:

– Light dispersion can reduce the brightness of specific areas.

– Not ideal for applications requiring focused light transmission.

Laser Etching

Laser etching involves creating icons, symbols, or graphics on the switch surface. The process starts with a base layer of natural or semi-transparent silicone, which is then coated with an opaque surface color (typically black or gray). The laser removes the surface color to reveal the base layer, allowing light to shine through the etched areas when illuminated.

Pros:

– Produces precise and clear icons with sharp illumination.

– Allows for high customization of designs and symbols.

Cons:

– Requires multiple layers of material and precise laser work.

– The light transmission is limited to the etched areas, which may not create an ambient effect.

Light Pipes

Light pipes are optical components integrated into the silicone rubber to channel light from LEDs directly to the desired areas. This method ensures high light transmission and minimal light loss, providing bright and focused illumination.

Pros:

– Delivers high-intensity and pure light transmission.

– Ideal for applications requiring clear and bright icons.

Cons:

– Can be more complex to design and integrate.

– Requires precise alignment with the LEDs for optimal performance.

For a soft, ambient glow, semi-transparent silicone buttons are an excellent choice. However, if precise and bright illumination of icons is needed, laser etching is the preferred method. For applications that demand high light transmission and minimal dispersion, incorporating light pipes into the design is the best solution. Each method offers unique benefits and can be selected based on the specific requirements of the device and desired lighting effects.

Light Pipes for Rubber Switch Buttons

A light pipe is a transparent rod made from clear plastic, glass, or high-transparency silicone rubber. These optical components transmit light from the bottom to the top of the pipe, freeing design constraints by eliminating the need for LEDs to be mounted directly on the panel. Light pipes help diffuse light to prevent hot spots, which can affect the safe operation of a device.

Choosing the Right Material

The application should be the primary consideration when selecting a material for the light pipe. Different materials offer varying levels of transparency, durability, and ease of integration.

Benefits of Light Pipes for Numeric Switches

Light pipes are particularly advantageous for silicone rubber switches requiring light indicator functions. They are ideal when laser etching is either unsatisfactory or too complex due to intricate symbol designs.

Designing and Manufacturing Light Pipes for Keyboards

There are two main types of light pipes for silicone rubber keyboards:

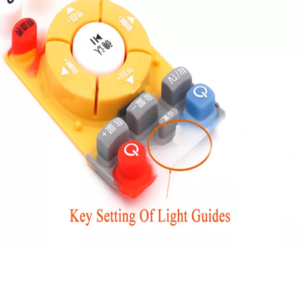

- Integrated Light Pipes: These are incorporated directly into the switches.

- Separate Light Pipes: These require manual assembly onto the switches.

Each type offers unique advantages depending on the specific requirements of the keyboard design and the desired lighting effects.

Integration of Light Pipes in Silicone Keyboards

The decision to mold light pipes together with silicone keyboards or to mold them separately depends on the overall keyboard design. If the light pipe’s shape aligns with the silicone buttons or keys and is designed on the keyboard’s surface rather than inside or underneath, molding them together is feasible.

Multicolor Keyboard Buttons

In cases where the keyboard features multicolor buttons or keys, which are produced using key-setting processes, silk-screen printing, or other methods, two scenarios for integrating light pipes can occur:

1.Integrated Light Pipes:

If mixing colors in the pad base (not in the keys) is acceptable, transparent light pipes can be compression molded together with the entire switches.

Example: Transparent Silicone Light Pipe Molded with Entire Switches

2.Protective Caps for Painted Keyboards

For keyboards with painted surfaces, it’s essential to protect the clear light pipes from getting painted over. Designing protective caps or covers is necessary to ensure the integrity of the light pipes during the painting process. These protective covers should fit snugly over each light pipe to prevent any paint from obscuring their clarity.

Example: Protective covers should be precisely fitted to each light pipe to maintain clarity and cleanliness during painting.

Creating Clear Light Pipes for Silicone Switches

When the design of silicone switches doesn’t allow for covering the keycap with a light pipe, laser etching provides a solution. For instance, if the light pipe is located beside the switches button too tightly to accommodate a keycap, the light pipe can be painted together with the entire switches. Then, the color layer can be laser-etched to maintain a clean and clear top surface of the light pipe.

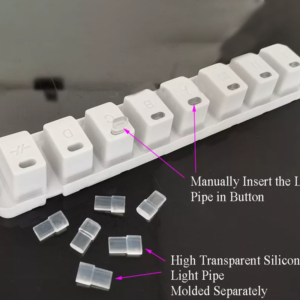

Creating Separate Light Pipes

When considering how to make separate light pipes, the primary concern is determining the requirements for light transmittance.

High Light Transmittance Requirements:

Achieving high light transmittance requires using good mold steel and meticulous mold finishing. Harder steel with fine polishing to a mirror finish can meet these needs but may increase mold costs. However, if the light pipe dimensions are too small, achieving precise mold finishing becomes challenging, and mold costs may escalate.

Optimizing Light Transmittance:

Using high-transparent silicone material for the light pipe can also enhance light transmittance in addition to mold steel and finishing considerations.

Balancing Cost and Performance:

For cost-saving purposes, using common mold steel and finishing without extensive polishing may be more economical, albeit affecting light transmittance. Additionally, employing high-transparent silicone material for the light pipe can offset some loss in transmittance.

The goal of incorporating light pipes in or on a keyboard is to minimize light loss, enhance uniform distribution of daylight, and improve luminance gradient across the room under variable conditions. Different requirements necessitate different processing methods for light pipes, each with varying development costs.

However, it’s crucial that the bottom surface of the light pipe is also transparent or clear. This requires the base pad for the silicone switches to be transparent initially. The resulting effect of this method ensures optimal illumination without compromising the aesthetics of the switches.

Additionally, the design process should cover regulatory and compliance aspects related to backlighting, especially in safety-critical applications such as automotive and medical devices. Compliance with industry standards and certifications is critical to ensuring the reliability and safety of backlighting solutions, thereby increasing manufacturer and end-user confidence.

In summary, the art and science of silicone switch backlight design encompasses countless technical, aesthetic, and functional considerations. By integrating innovative LED technology, thoughtful design principles and rigorous testing, manufacturers can improve the performance and user experience of silicone switches in different applications. We say goodbye for now and we encourage you to contact us if you have any questions or concerns about silicone switch backlight design. Next time, may your switches sparkle and your designs light up the world!