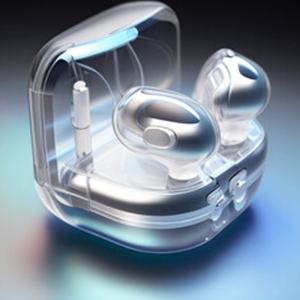

Product Overview:

Introducing our Grade Silicone Mask for Kids – the perfect blend of safety and comfort for your little ones. Crafted with care using high-grade silicone, these masks are designed to provide a snug and secure fit, ensuring your kids can breathe easy while staying protected. With vibrant colors and a playful design, we’ve made wearing masks fun and stylish for the little trendsetters. Let’s dive into the fantastic world of safety, shall we?

Product Specifications:

– Material:High-grade silicone

– Design: Kid-friendly and playful

– Fit:Snug and comfortable

– Colors: Vibrant and appealing

– Adjustability:Easily adjustable straps for a personalized fit

– Cleaning:Simple to clean and reusable for eco-friendly use

– Age Range:Specially crafted for kids, ensuring a perfect fit for their adorable faces

Production Process:

-

Material Sourcing and Quality Control

– The first step involves sourcing medical-grade silicone that meets strict safety and regulatory standards. The silicone is tested to ensure it’s hypoallergenic, non-toxic, and suitable for medical applications.

-

Design and Prototyping

– Once the material is selected, the design team creates prototypes of the mask. This step involves 3D modeling and using CAD software to ensure the mask fits comfortably on a child’s face and meets medical requirements. Prototypes are usually tested for fit, comfort, and functionality.

-

Molding and Injection

– After the design is finalized, silicone injection molding is used to shape the mask. The silicone material is injected into a custom mold under high pressure to form the mask’s structure. This process ensures precision and allows for mass production.

-

Curing and Hardening

– The silicone mask is then placed in an oven or autoclave for curing. This step uses heat to fully cure the silicone, ensuring it hardens to the right consistency while maintaining its flexibility and durability.

-

Post-Processing and Trimming

– After curing, the mask is removed from the mold and excess silicone is trimmed off. This step ensures that the edges are smooth and that the mask has no sharp or uncomfortable areas.

-

Surface Treatment

– The mask undergoes a surface treatment to remove any contaminants and to improve the texture. This may involve washing, sterilizing, or using specific coatings to ensure the mask is clean and safe for children’s use.

-

Assembly and Fitting

– After the silicone mask is fully formed, any additional components like straps, nose clips, or valves are added. These are carefully fitted to ensure that the mask is easy to wear, adjustable, and comfortable for children.

-

Quality Control and Testing

– The mask goes through a thorough quality control process, which includes testing for fit, comfort, airtightness, and safety. The mask is checked for defects and must pass stringent safety standards before it can be approved for medical use.

-

Sterilization

– Before being packaged and shipped, the silicone mask is sterilized using either autoclaving or other sterilization methods to ensure it is free of any bacteria or contaminants.

-

Packaging

– Finally, the mask is packaged in medical-grade packaging to ensure hygiene and safety during storage and transportation. The packaging is also designed to be child-friendly, with clear instructions for use and care.