Description:

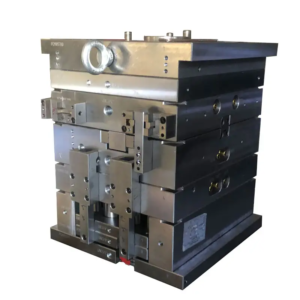

The plastic car battery container box mould for auto parts is designed for the efficient production of durable battery housings used in vehicles. This mould is primarily crafted using advanced injection molding techniques, ensuring high precision and optimal performance. Typically made from high-quality steel or aluminum, these molds are engineered to withstand rigorous production demands while delivering consistent results. Our factory specializes in providing OEM services, offering customizable solutions that cater to your specific requirements. With our expertise in manufacturing and a commitment to quality, we ensure timely production, cost-effective solutions, and unmatched durability in every mould we create.

Features:

| Mold Specifications | Details |

| Mold Type | Plastic Injection Mold |

| Mold Material Options | P20, 718, 738, NAK80, S136 |

| Mold Base Standards | HASCO, DME, MISUMI, JIS, LKM |

| Mold Runner System | Cold Runner / Hot Runner |

| Mold Gate Options | Slide Gate, Sub Gate, Pin-point Gate |

| Cavity | Single or Multi-Cavity |

| Design Software Supported | UG, PROE, CAD, SOLIDWORKS |

| Molding Equipment Used | CNC, Wire Cutting, Milling Machine, EDM |

| Compatible Raw Materials | ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS |

| Packaging Method | Wooden pallet or carton |

| OEM Services | Available—please provide 2D/3D files or samples |

| Lead Time | Approximately 30 days |

Production Process:

- Design and Engineering: The process begins with the creation of detailed design specifications using advanced CAD software. Engineers develop 2D and 3D models to ensure precision and functionality.

- Material Selection: Suitable materials, such as P20, 718, or NAK80 steel, are chosen based on the required durability and performance characteristics of the mould.

- Machining: High-precision machining processes, including CNC machining, wire cutting, and EDM, are employed to fabricate the mould components according to the design specifications.

- Assembly: Once all components are machined, they are meticulously assembled to form the complete mould. This stage ensures that all parts fit perfectly and function as intended.

- Testing and Quality Control: The assembled mould undergoes rigorous testing to verify its performance and quality. Any necessary adjustments are made to achieve the desired specifications.

- Production: The finalized mould is then used in the injection molding process to produce the plastic car battery containers, ensuring consistent quality and precision in each unit.

- Finishing and Packaging: After production, the mould may undergo surface treatment or finishing processes, and is then packaged securely for delivery.

Finishing Options:

- Polishing: This finishing technique enhances the surface smoothness and overall aesthetics of the mold, resulting in a reflective finish that reduces friction and improves the release of molded parts.

- Matte Finish: A matte finish is applied to create a non-reflective surface, which can help hide imperfections and provide a more subtle appearance. This finish is often preferred for applications requiring a more industrial look.

- VDI (Verein Deutscher Ingenieure): This standard refers to specific texture finishes, providing a range of surface patterns that can enhance both functionality and appearance. VDI textures are widely used in various industries to meet aesthetic and tactile requirements.

- SPI (Society of the Plastics Industry): SPI finishing standards define the surface finish grades for molds, ranging from smooth to rough textures. These standards ensure consistency and quality in mold finishes, catering to different application needs.

- Ball Burnishing: This advanced finishing process involves using spherical media to improve surface quality through a combination of pressure and sliding motion. Ball burnishing effectively reduces surface roughness and enhances the mold’s durability and performance.

Why Choose Us?

– Our expert mold design team delivers innovative design solutions tailored to meet your specific requirements, ensuring optimal functionality and performance.

– With a highly experienced production and quality control team, we guarantee efficient manufacturing processes and rigorous quality assurance, resulting in reliable and high-quality products.

– We offer comprehensive OEM services, allowing for customized solutions that align with your unique specifications and branding needs, ensuring a perfect fit for your product line.

– Our fast shipping services ensure that your orders are processed and delivered promptly, minimizing lead times and helping you stay on schedule with your production timelines.

Factory Show:

Our factory covers 4,500 square meters and has over 20 years of OEM experience. We utilize top-tier processing machinery, including Roders, Makino, Sodick, and YCM.

By leveraging advanced machining equipment and tooling technologies, we achieve micron-level precision in production. Our capabilities include creating ultra-precision components weighing as little as 0.02 grams and measuring just 0.1 mm in thickness.

Additionally, our ISO-certified Class 8 cleanroom ensures a reliable environment for manufacturing medical device components, meeting rigorous industry standards.