Description:

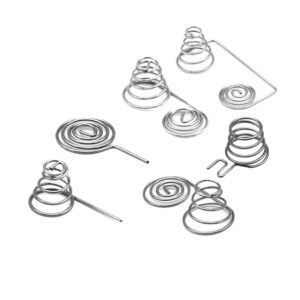

We specialize in the design, manufacturing, and assembly of custom metal clips, offering a wide range of shapes and sizes to suit any application. Our process includes precision stamping, forming, and secondary operations like vacuum hardening and oil quenching to enhance durability. Additionally, we provide various plating options to ensure optimal performance and corrosion resistance. Metal clips are available in different material compositions to meet application requirements and budget considerations. Contact us today for a competitive quote, customized to your clip’s size, shape, and material specifications.

Details:

| Specification | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Stainless Steel / Metal |

| Type | Hardware Parts |

| Size | Customized Size |

| Surface Treatment | Galvanized / Custom |

| Certificate | ISO 9001:2015 / IATF 16949 |

| Delivery | By sea / air / express |

| Service | Customized OEM |

| Application | Various Industrial |

Production Process:

-

Design and Engineering

The process begins with the creation of detailed design drawings. This involves collaboration between the client and the engineering team to ensure that the specifications meet the required standards. CAD software is often used to create precise 2D and 3D models, which serve as the blueprint for the production.

-

Material Selection

Once the design is finalized, the next step is to select the appropriate materials. Factors such as strength, corrosion resistance, and cost-effectiveness are considered. Common materials for metal clips include stainless steel, aluminum, and various alloys.

-

Prototyping

Before mass production, a prototype of the metal clip is created. This allows for testing and validation of the design. Any necessary adjustments can be made based on performance evaluations and client feedback.

-

Tooling and Setup

After the prototype is approved, tooling is developed. This includes creating molds, dies, and other necessary equipment for manufacturing. The production line is then set up to accommodate the specific requirements of the metal clip.

-

Production

With everything in place, the actual production begins. This may involve processes such as stamping, bending, and welding, depending on the design. Quality control measures are implemented throughout this stage to ensure that each clip meets the specified standards.

-

Finishing

Once the clips are produced, they undergo finishing processes. This may include deburring, polishing, and applying protective coatings to enhance durability and appearance.

-

Quality Assurance

A thorough quality assurance process is conducted to inspect the final products. This includes dimensional checks, material testing, and functional assessments to ensure that the clips meet all specifications and standards.

-

Packaging and Shipping

Finally, the metal clips are packaged for shipment. Proper packaging is essential to prevent damage during transit. Once packaged, the clips are shipped to the client or designated location.

Why Choose Us:

Extensive Industry Experience

Since 1998, we have specialized in the spring manufacturing industry, bringing years of expertise to every project.

Sample Availability

We offer sample approval within 7 days, and if we have existing tooling, samples are provided free of charge.

Fast Delivery

Typical delivery time is within 10 days, ensuring quick turnaround for your orders.

Exceptional Quality and Service

Our commitment is to deliver competitive pricing, excellent customer service, and superior product quality.

Competitive Pricing

Our pricing is fair and highly competitive compared to other manufacturers in the market.

Vast Experience

With 20 years of experience, we have built a strong reputation with customers across the U.S., Europe, and Australia. Our team is dedicated to sales excellence and maintaining stringent quality control standards.

Application Industry:

-

Automotive Industry

Metal clips are essential in the automotive sector for securing components such as panels, wiring harnesses, and trim pieces. They ensure structural integrity and facilitate easy assembly and disassembly during manufacturing and repairs.

-

Electronics

In the electronics industry, metal clips are used to hold circuit boards, connectors, and other components in place. Their ability to provide reliable fastening while maintaining electrical conductivity makes them ideal for various electronic devices.

-

Construction

Metal clips play a crucial role in construction applications, where they are used to secure insulation, ductwork, and other building materials. They provide stability and support, ensuring that structures meet safety and performance standards.

-

Furniture Manufacturing

In furniture production, metal clips are employed to assemble and secure various components, such as frames and upholstery. They enhance durability and ease of assembly, contributing to the overall quality of the finished product.