Types of Tooling

- Prototype Tooling

- Production Tooling

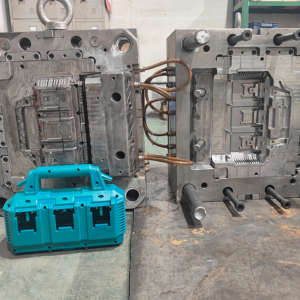

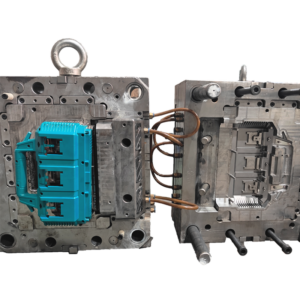

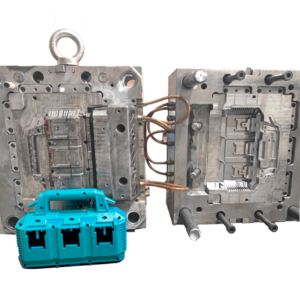

We specialize in crafting bespoke plastic injection molds and parts designed for an array of battery applications. Our expertise covers the production of molds for battery cases, boxes, containers, enclosures, covers, lids, caps, and vent plugs. We provide comprehensive services, ranging from tooling to mass production. Alternatively, you have the option to bring your own molds, and we’ll customize parts to your specifications. Explore our diverse range of battery box molds, each meticulously tailored to accommodate various battery types and specifications.

Mould Making Process

- Product3D checking and DFM

- Tooling design and get approval

- Mold material purchase

- Bold building of CNC and EDM process,

- Auxiliary machining such as wire EDM, drilling and grinding

- Polishing

- Mold assembly

- Quality Control

- T0 and P0 sample for customer approval

- Packing and delivery

Tight Tolerances

Using wire EDM, 5-axis CNC and other high-precision equipment to achieve tolerances as 0.01mm.

Materials

- P20 (P20HH)

- S136 (S136H)

- NAK80

- H13

- 718 (718H)

- 2738 (P20+Ni)

- 2316

- MoldMAX

- Aluminum

Our service including:

- Mold Design and Engineering Support

- Material Selection and Recommendations

- Mold Manufacturing

- Prototype Development

- Mold Trial and Adjustment

- Rapid Delivery

- Quality Assurance

- Sustainability Practices

Capability:

- High Precision Design and Manufacturing

- Precise Reproduction of Complex Geometries

- Multi-Cavity Design for Enhanced Efficiency

- High-Temperature Resistant Materials and Manufacturing Processes

- Precision Cooling System

- Longevity and Maintenance

- Quality Control System