Discover Superior Shower Head Nozzle Injection Molds in Xiamen!In Xiamen, a multitude of manufacturers offer shower head nozzle injection molds, each boasting unique advantages tailored to specific models and applications. Amidst this competitive landscape, Toolingsun emerges as a standout player, renowned for its unwavering commitment to excellence in the research, development, and sales of injection mold products.

At Thesun Industry, we specialize in crafting premium shower spray nozzles, spray nozzles, filters, filter elements, and more. Our distinguished expertise is underpinned by a team of seasoned technical professionals, cutting-edge production technology, rigorous testing protocols, and stringent management systems.

With a steadfast dedication to quality assurance, we guarantee unparalleled product stability and dependable performance. Experience the difference with Toolingsun – your trusted partner for superior shower head nozzle injection molds in Xiamen!

Features:

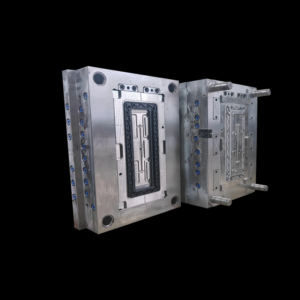

| Feature | Details |

| Mold Cavity | Single |

| Plastic Material | ABS |

| Process Type | Single-Process Mode |

| Application | Household Appliances, Home Use |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certifications | ISO |

| Standard | HASCO |

| Customization | Available |

| After-sales Service | 3 Years |

| Packaging | Customized or Color Box |

| Specifications | 290x285x90mm |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 600 sets per year |

Quotation Process:

-

Requirements Assessment:

Submit 2D/3D drawings or samples to initiate the quotation process.

-

Mold Design:

Prepare and provide mold design drawings for customer approval.

-

Mold Manufacturing:

Begin mold manufacturing upon design confirmation.

-

Mold Trial:

Produce first shot samples for customer evaluation.

-

Sample Approval:

Customers review and approve the samples.

-

Mold Adjustment:

Implement necessary modifications to the mold if required.

-

Mold Delivery:

Deliver the mold upon receipt of the third payment.

-

Post-Sales Support:

Benefit from complimentary 12-month warranty service for added assurance.

Injection Molding Techniques for Plastic and Rubber Products:

-

Rubber Injection Molding:

Utilizes direct injection of a rubber compound into the mold for vulcanization. Benefits include shortened molding cycles, heightened production efficiency, and superior product quality.

-

Plastic Injection Molding:

Involves injecting molten plastic into a mold, which then cools and solidifies to form desired plastic parts. Widely employed across various plastic products, with polystyrene being a popular material choice.

-

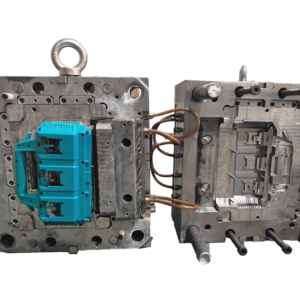

Overmolding and Insert Molding:

Processes that integrate multiple materials or components during injection molding, eliminating the need for further assembly. Complex features like bosses, ribs, and threads can be seamlessly incorporated in a single operation.

Processes that integrate multiple materials or components during injection molding, eliminating the need for further assembly. Complex features like bosses, ribs, and threads can be seamlessly incorporated in a single operation.

Thesun Industry excels in the design and production of precision injection molds and bespoke molded plastic components. Our expertise spans the entire spectrum of product development, encompassing initial design, development, and manufacturing stages. We offer holistic solutions tailored to facilitate new product innovation and realization.