Overview:

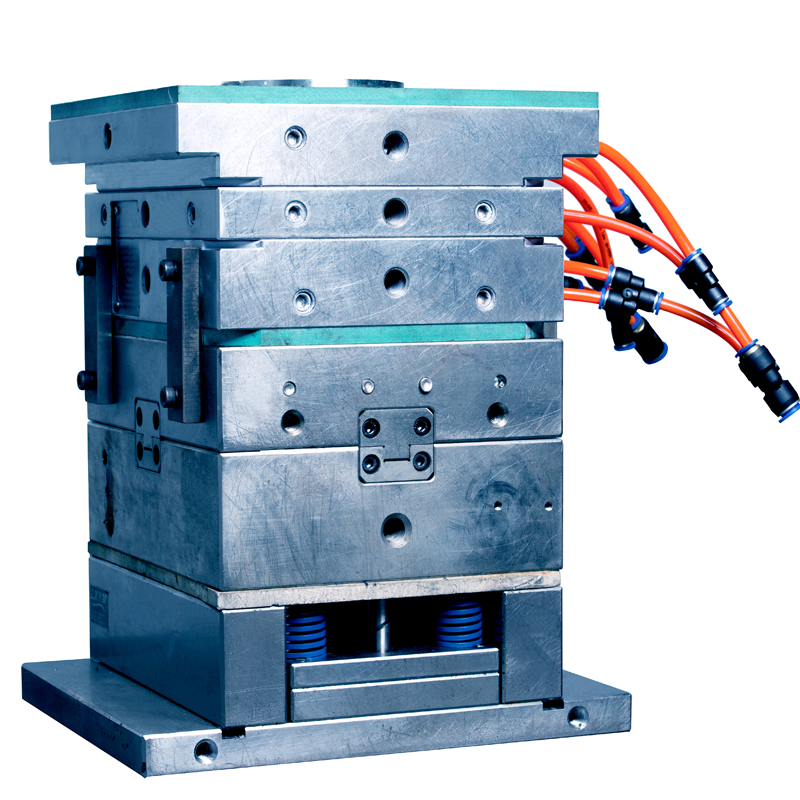

LSR injection molds are advanced molding tools designed specifically for producing high-quality Liquid Silicone Rubber (LSR) products. Utilizing state-of-the-art process technology, these molds achieve precise and intricate shaping, ensuring exceptional dimensional accuracy and surface quality in the final products. Their compatibility with LSR’s unique properties allows effective utilization, while their heat-resistant characteristics ensure the durability of the molds.

Key Features:

| Cavity | Multi-cavity |

| Surface Treatment | Polish |

| Working Temperature | -40℃-300℃ |

| Certification | RoHs, ISO/IATF16949 |

| Mould Life | <500000 times |

| Logo | Custom |

| After-sales Service | Available |

| Sample Time | According to your design |

| Transport Package | According to Your Requirements |

| Trademark | OEM |

| Production Capacity | 50 Sets / Month |

The Function Of LSR Injection Mold:

- Precision Molding:LSR injection molds are designed to achieve precise and intricate molding of Liquid Silicone Rubber, ensuring accuracy in the final product’s dimensions and details.

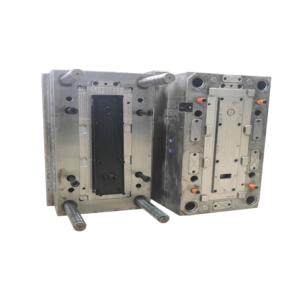

- Material Compatibility: These molds are engineered to accommodate the unique properties of Liquid Silicone Rubber, allowing for effective and consistent molding of the material.

- High-Temperature Resistance: LSR injection molds are constructed with materials that can withstand the high temperatures involved in the LSR molding process, ensuring durability and longevity.

- Flexibility and Versatility:The molds offer flexibility in molding complex shapes and versatile designs, making them suitable for a wide range of applications across various industries.

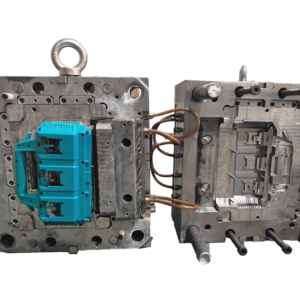

- Consistent Quality:LSR injection molds contribute to the production of high-quality silicone products with consistent characteristics, meeting stringent quality standards.

- Efficient Production:Designed for efficiency, these molds facilitate the rapid and cost-effective production of LSR components, streamlining the manufacturing process.

- Customization Capabilities:LSR injection molds can be tailored to specific product requirements, allowing for customization in design, size, and functionality.

LSR injection molds demonstrate flexibility and versatility in the production process, capable of meeting various design requirements. By optimizing the molding process, these molds offer efficient production capacity, providing customers with a fast, reliable, and cost-effective solution. Their consistent quality and customization capabilities make LSR injection molds an ideal choice for producing high-quality silicone rubber products across a wide range of industries and applications. Choosing LSR injection molds ensures highly customized solutions, guaranteeing products meet the highest standards while improving efficiency and reducing costs in the manufacturing process.