Overview:

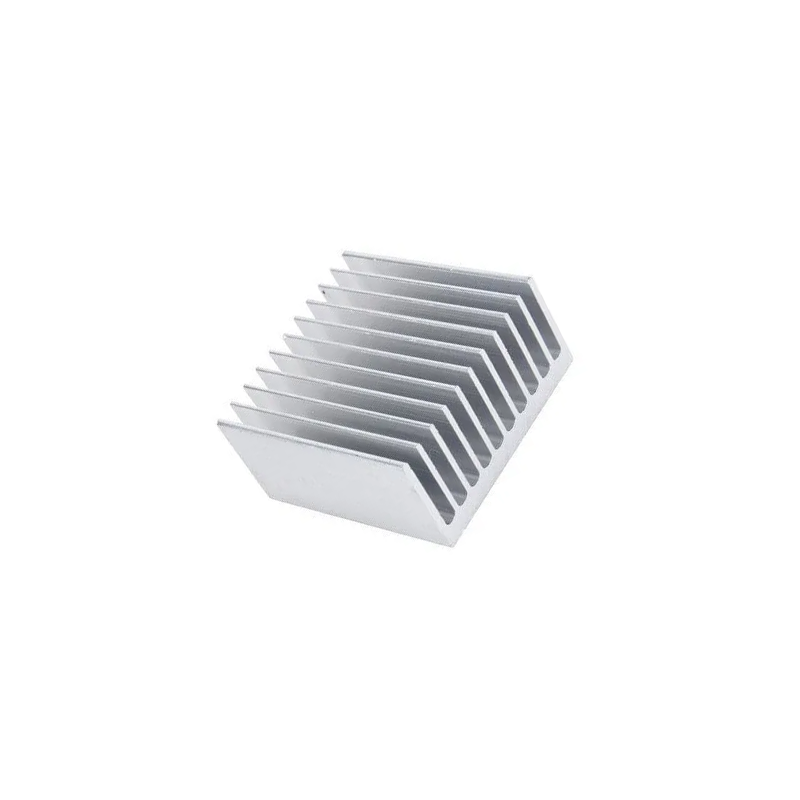

Extruded heat sinks are crafted using a specialized process, pushing material through a die for intricate cross-sections. We employ the high thermal conductivity aluminum alloy A6063 at FM, chosen for its unique properties despite being challenging to work with. Ideal for high-volume production due to lower non-recurring engineering (NRE) costs, molds are made through wire EDM with a lead time of 4-6 weeks. This method proves most economical when post-machining is unnecessary, minimizing stress-related distortion. Extruded heatsinks, with thin fins and an 8:1 aspect ratio, optimize performance, exemplified by the Platefin extruded heat sink designed for efficient natural convection heat dissipation.

Basic Information:

| Material | Aluminum,Copper |

| Detailed Size | As the below drawing,or as per custom design |

| Max Aspect Ratio( Fin Height / Fin Gap) | More than 20 times aspect ratio heatsink can be extruded by 800 Tons–6000 Tons extruding machine by most advanced technology |

| Max Width | Ultra wide extruded heatsink can be made by our unique friction welding technology |

| Standard Mold Qty | 30,000+ sets standard molds in stock for your option,saving your R&D cost |

| Sample Service | Samples with differernt sizes are availabe for prototypes test within 1 week |

| Production Process | Profiles Extruding—Cutting—CNC Machining(Milling, Drilling,Tapping)—Deburring— Cleaning— Inspecting–Packing |

| Surface Treatment | Degreasing,(Black) Anodizing,Sand Blasting,Painting,Chromating and Laser marking |

| Reference Standard | GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

| Experience | More than 20 years professional manufacturing experience |

|

Application |

LED Lighting,Inverter,Welding Machine,Communication Device,Power Supply Equipment,Electronic Industry,Thermoelectric Coolers/Generator,IGBT/UPS Cooling Systems,etc. |

Our Advantages:

- Seasoned engineering professionals;

- Comprehensive QC inspection throughout the entire process, ensuring a robust quality system before, during, and after processing;

- Prompt and efficient communication, fostering a constructive relationship between business and production, with a precise understanding of customer requirements.