Description:

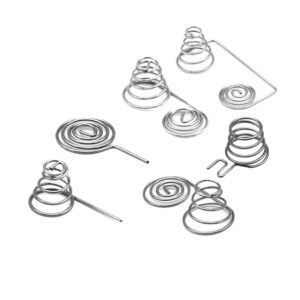

Heat sinks are cooling devices designed to dissipate heat from electronic components. Their primary function is to prevent overheating, ensuring optimal performance and longevity of devices.

Constructed from metals like aluminum or copper, heat sinks feature fins to increase surface area for efficient heat transfer to the surrounding air. They find applications in various fields, including electronics, computers, and automotive, where efficient heat dissipation is critical for device functionality and reliability.

Specification:

| Size and Weight | Customized |

| Material | Aluminum,copper |

| Color | Customized according to the pantone |

| Advantage | Increased Efficiency,Stability |

| Application | electronics, computers |

| OEM | Available |

| Sample | Can be provided |

| Price Term | EXW,FOB,CIF,DDP,DDU |

| Transportation | By Sea,Express |

Surface Treatment:

- Anodizing: Formation of an oxide layer on the surface through an electrolytic process, improving corrosion resistance and hardness.

- Nickel Plating or Nickel Alloy Plating: Application of a layer of nickel or a nickel alloy to enhance surface hardness, corrosion resistance, and appearance.

- Thermal Conductive Coating: Application of a coating with high thermal conductivity to improve heat transfer efficiency.

- Ceramic Coating: Application of a ceramic material to increase surface hardness and corrosion resistance.

- Anti-Oxidation Coating: Application of a coating to enhance resistance to oxidation, preventing its impact on heat transfer performance.

- Polishing: Mechanical polishing of the metal surface to increase surface smoothness and reduce heat transfer resistance.

- Anti-Fingerprint Coating: Application of a coating to make the surface more resistant to fingerprints, facilitating easier cleaning.

Our Service:

- Customized Solutions

- Sample Availability

- Swift Responses

- Dedicated to Satisfaction