3D Printing Service for Custom Parts

Experience the convenience of our on-demand 3D printing service, allowing you to effortlessly bring your custom parts to life through the power of 3D printing.

Certifications

ISO 9001:2015 | AS9100D

150,000+

Parts printed each month

50,000+

Product developers served

120+

Additive manufacturing machines

Our 3D Printing Service

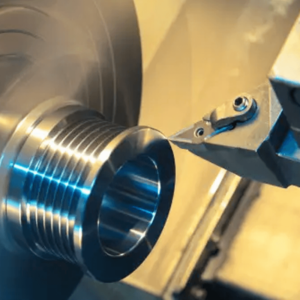

ThesunIndustry’s 3D Printing Service enables you to 3D Print your custom part on demand. With a focus on 3D printing, our team comprises skilled mechanical engineers, reverse engineers, CNC engineers, prototype craftsmen, silk screen printing technicians, and surface treatment engineers. Our state-of-the-art facilities house two 3D printers (SLA laser rapid prototyping machines), six CNC machining centers, UV machines, ovens, and other specialized spraying equipment. Additionally, we offer auxiliary facilities for spray painting, silk screen printing, pad printing, and more.

Why Choose Our 3D Printing Service

Advanced Equipment&Technical

With cutting-edge 3D printing technology and a comprehensive range of equipment, we offer an extensive array of 3D printers (FDM, SLA, SLS, etc.) and printing materials suitable for diverse applications. Our professional 3D modeling software enables precise and detailed digital model creation. Additionally, we provide 3D scanners, heated beds, ultraviolet curing lamps, and post-processing equipment like sanding, painting, and drying apparatus to elevate the quality and aesthetics of the printed parts. At the forefront of innovation, our advanced equipment and technical expertise enable us to meet diverse demands and continually enhance our 3D printing capabilities, ensuring top-notch products and services for our customers.

Wide Material Selection

For Fused Deposition Modeling (FDM), commonly used plastics like PLA and ABS offer excellent printability and structural integrity. In Stereolithography (SLA) and Digital Light Processing (DLP), photopolymer resins enable high-detail and precision prints for intricate designs and models. For Selective Laser Sintering (SLS), metal powders such as stainless steel and titanium deliver robust and functional parts with excellent mechanical properties. Furthermore, our repertoire includes composite materials and food-safe options for specialized applications, showcasing our commitment to providing personalized and innovative solutions to meet the diverse demands of 3D printing projects.

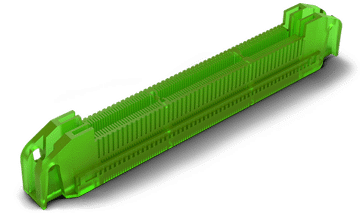

Comprehensive 3D Printing Solutions

Our state-of-the-art facility boasts over 10 sets of 3D printing machines to producing your 3D printing parts.Our one-stop service provides a complete range of 3D printing solutions. From design to production, we utilize advanced 3D modeling software and a variety of 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), covering a wide range of materials. We also offer efficient post-processing equipment, such as sanding, painting, and drying, to optimize the appearance and surface quality of the parts.

Strict Quality Control

We rigorously manage printing parameters, such as temperature, speed, and layer height, ensuring precise and consistent parts. Advanced post-processing techniques, including sanding, painting, and coating, enhance the appearance and surface quality of our 3D printed components. Comprehensive quality inspections, encompassing dimension measurements, physical tests, and visual checks, guarantee that our products meet the highest standards.

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Seamless Customization

We collaborate closely with you to bring your vision to life. With a wide array of materials, colors, and finishes, your creative ideas take shape with precision and unmatched quality.

Fast Delivery Time

We can start manufacturing immediately according to your needs, achieving rapid delivery, enabling you to seize the market opportunities and meet urgent customer demands.

Metals

- Aluminum

- Cobalt Chrome

- Inconel

- Stainless Steel

- Titanium

Plastics

- ABS

- PA (Nylon)

- Polycarbonate

- Polypropylene

Elastomers

- Digital photopolymer

- TPU

- True Silicone

Note:The 3D printing technology is constantly evolving, and new materials may emerge in the future, so this list may not be exhaustive. When choosing materials, factors such as printer compatibility, required performance, application areas, and cost need to be taken into consideration.

Our 3D Printing General Tolerances (2023/10/9 Updated)

| Description | Tolerance Notes |

|---|---|

|

Part Size |

We can accommodate 3D printing up to 24" x 36" x 36" without the need to split and bond parts. |

|

Minimum Feature Size |

0.030" - 0.060" is typical. |

|

Minimum Wall Thickness |

0.020" - 0.060" is typical. |

|

Clearance Between Features |

At least 0.030" |

Surface Finish Options for 3D Prints

1.Sanding:

Sanding is a common 3D printing finishing method. It involves using coarse to fine sandpaper to smoothen the part's surface. However, it requires caution as it can remove too much material. For a shinier finish, polishing cloths or coatings can be used.

2. Grinding

Grinding complements 3D printing for surface finishing. It achieves fine surface finishes and maintains tight tolerances, even in hard-to-reach areas. Compatible with various materials, it enhances the quality of 3D printed parts.

3. Bead Blasting

Bead blasting is a popular 3D printing finishing technique. Small beads are blasted on the surface, flattening imperfections. It's quicker than sanding and reaches inaccessible areas. Similar processes include sandblasting, shot peening, and water blasting with minor differences.

4. Plating

Plating enhances 3D printing parts with benefits like improved material properties, durability, and aesthetics. It adds wear resistance and corrosion protection to plastic parts and useful properties to metallic parts. Aesthetic appeal is also enhanced with metallic coatings like gold, silver, and chrome.

5. Painting

Painting improves the appearance of 3D printing parts, offering various color choices. A coat of primer and putty smoothens the surface and prepares it for painting. Additionally, painting provides a degree of sealing, addressing the porosity issue common in 3D printing.

Advantages of 3D Printing

Building parts layer-by-layer brings about many benefits that open up design possibilities that were previously unachievable through traditional processes like injection molding, machining, or casting.

- 1.Complex, organic geometries with limited impact on part cost

- 2.Consolidation of multi-component assembly into a single part

- 3.No upfront tooling costs

- 4.Fast production for parts within 24 hours

- 5.Internal features for advanced heat transfer and flow applications

Common 3D Printing Applications

Additive manufacturing can be leveraged for both rapid prototyping and production in aerospace, medical, automotive, and other large industry sectors. Examples of typical parts, include:

- Form and fit prototypes

- Housings and enclosures

- Medical devices

- Snap fits

- Jigs and fixtures

- Heat exchangers and heat sinks

- Engine components

- Fuel injectors

- Surgical instrumentation